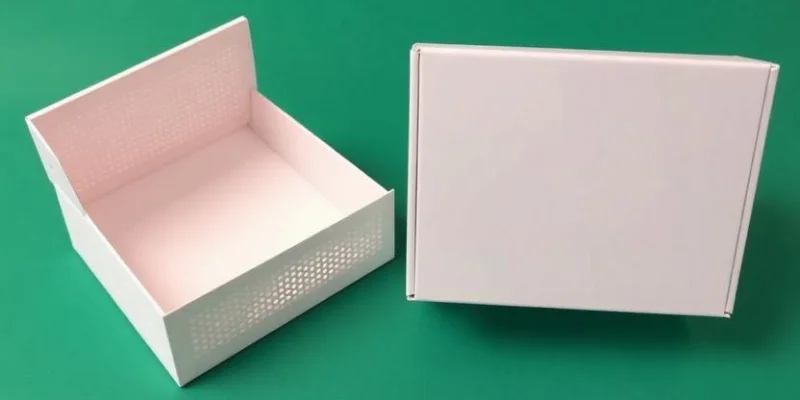

Packaging isn’t just about protection anymore—it’s about presentation, usability, and brand identity. One of the most functional innovations in modern packaging design is the custom perforated boxes. These boxes are designed with tiny, evenly spaced holes (perforations) or tear-away lines that make opening, dispensing, and handling the product easier for customers.

Whether it’s a food brand, a pharmaceutical company, or a cosmetic manufacturer, custom perforated boxes are now a must-have packaging solution. They allow for controlled access, better ventilation, and a premium unboxing experience, all while being cost-efficient and sustainable.

In this guide, we’ll explore everything from materials and industries to sizes, costs, and design options of custom perforated boxes.

What Are Custom Perforated Boxes?

Custom perforated boxes are cardboard or corrugated paperboard boxes with pre-cut dotted lines or holes. These lines can be torn, pushed, or folded easily, allowing parts of the box to open selectively.

They are commonly used for displaying products, easy opening, or dispensing single items—making them both functional and visually appealing.

Common Materials Used:

- Cardboard (300–400 GSM) – Lightweight and economical.

- Kraft Paper – Eco-friendly and recyclable option.

- Corrugated Board – Ideal for heavy or bulk items.

- Rigid Board – Premium, luxury packaging with strength.

- Duplex Board – Smooth printing surface for branding.

Features of Custom Perforated Boxes

| Feature | Description |

|---|---|

| Tear-line design | Pre-cut dotted lines for easy tearing or opening |

| Ventilation holes | Ideal for food, bakery, or agricultural use |

| Customizable printing | Add brand logo, color, and pattern |

| Eco-friendly options | 100% recyclable and biodegradable |

| Versatile usage | Suitable for retail, food, medical, and industrial products |

NLP & Semantic Keywords:

Custom packaging, eco boxes, die-cut perforation, retail display box, sustainable packaging, easy-open box, printed perforated packaging, corrugated perforated boxes, tear strip design, custom branding box.

Why Use Perforated Packaging?

- Ease of Access – Perforations allow quick product access without damaging the box.

- Customer Convenience – Perfect for retail shelves and quick dispensing.

- Improved Presentation – Enhances display visibility and aesthetic appeal.

- Cost-Effective – Requires minimal materials and design cost.

- Eco-Conscious Choice – Recyclable materials promote sustainability.

- Better Airflow – For food or agricultural items that need ventilation.

Industries That Use Custom Perforated Boxes

Custom perforated boxes serve multiple industries, from food and cosmetics to electronics and pharmaceuticals. Below is a breakdown of the major sectors that rely on this type of packaging:

1. Food and Beverage Industry

Perforated boxes are widely used for bakery items, snacks, beverages, and take-away foods.

Common Products:

- Pizza boxes with perforated tear strips

- Bakery display trays

- Beverage can carriers

- Snack boxes and popcorn packaging

- Sandwich wraps and deli paper boxes

Purpose: Easy access and improved ventilation for freshness.

2. Cosmetics and Personal Care

Cosmetic brands use perforated packaging for both display and subscription boxes.

Common Products:

- Lip balm display boxes

- Perfume testers

- Lotion and cream sample boxes

- Makeup kit display trays

Purpose: Tear-away displays and attractive shelf presence.

3. Pharmaceutical Industry

Pharma companies prefer perforated packaging for unit-dose packaging, medicine display trays, and sterile item containers.

Common Products:

- Tablet strip boxes

- Syringe and vial display boxes

- Bandage dispensers

- Mask and sanitizer boxes

Purpose: Hygiene control and easy product dispensing.

4. Retail and E-commerce

Retail stores use perforated boxes for point-of-purchase displays, subscription packaging, and inventory management.

Common Products:

- Display boxes for chocolates or gum

- Tear-top retail display packaging

- Countertop dispensers

- Promotional or seasonal packaging

Purpose: Quick assembly and easy product removal.

5. Electronics and Hardware

For electrical and mechanical goods, perforated boxes offer secure yet easy-to-open packaging.

Common Products:

- Battery packaging boxes

- Light bulb holders

- Cable and wire dispensers

- Small appliance boxes

Purpose: Protection and usability with a clean unboxing process.

6. Agriculture and Floral Industry

Ventilated perforated boxes are used for packaging fruits, vegetables, and flowers.

Common Products:

- Fruit and vegetable trays

- Flower transport boxes

- Seedling packaging

Purpose: Allow airflow to prevent spoilage and maintain freshness.

Standard Sizes of Custom Perforated Boxes

While perforated boxes can be customized to any dimension, several standard industry sizes are most commonly used:

| Box Size (inches) | Use Case | Material Type | Average Cost (USD/unit) |

|---|---|---|---|

| 6 x 4 x 2 | Small cosmetic or food items | Cardboard | $0.25 – $0.40 |

| 8 x 6 x 4 | Bakery or retail display | Corrugated | $0.45 – $0.60 |

| 10 x 8 x 4 | Snack boxes or small electronics | Kraft or Duplex | $0.55 – $0.75 |

| 12 x 10 x 4 | Pharmaceutical or tool packaging | Corrugated | $0.70 – $0.95 |

| 14 x 10 x 4 | Large display boxes or combo kits | Corrugated | $0.90 – $1.20 |

| 16 x 12 x 6 | Industrial or agricultural packaging | Heavy corrugated | $1.20 – $1.60 |

Note:

Prices vary depending on printing type (offset, digital, UV), lamination (gloss/matte), and order quantity.

Customization Options

To ensure that your packaging aligns perfectly with your brand identity, custom perforated boxes can be personalized in multiple ways:

1. Printing Options

- Offset Printing

- Digital Printing

- CMYK and Pantone Color Options

- Spot UV or Foil Stamping

- Embossing or Debossing for premium look

2. Coatings and Finishes

- Gloss or Matte Lamination

- Soft Touch Finish

- Aqueous Coating for moisture resistance

- Eco-friendly Kraft coating

3. Add-ons

- Die-cut Windows

- Tear Strips or Punch Holes

- Custom Inserts or Dividers

- Handles or Foldable Tabs

4. Branding Elements

You can add:

- Company Logo

- Product Details

- Barcodes and QR Codes

- Taglines or Slogans

These features help in marketing, retail recognition, and customer loyalty.

Advantages of Using Custom Perforated Boxes

| Advantage | Explanation |

|---|---|

| Enhanced Usability | Makes opening and dispensing simpler |

| Cost Savings | Uses standard cardboard materials |

| Eco-Friendly | 100% recyclable paper-based material |

| Custom Fit | Tailored to specific product dimensions |

| Brand Identity | Helps in consistent product branding |

| Protection | Prevents damage during transport and handling |

| Display-Ready | No need for separate display stands |

Cost Factors of Custom Perforated Boxes

The price of perforated boxes depends on several production and design factors:

- Material Choice – Kraft and cardboard are cheaper; rigid and corrugated cost more.

- Box Dimensions – Larger boxes require more material and labor.

- Quantity Ordered – Bulk orders significantly reduce cost per unit.

- Printing & Finishing – Full-color printing and lamination add cost.

- Add-ons – Windows, handles, or foil stamping increase price.

- Shipping & Location – Costs vary by manufacturer and delivery region.

Example Estimate:

- Small retail box (6x4x2) → $0.30 each (for 1000 units)

- Medium perforated display box (10x8x4) → $0.60 each (for 1000 units)

- Large industrial box (16x12x6) → $1.20 each (for 1000 units)

How to Choose the Right Perforated Box for Your Business

- Identify the Product Type – Food, cosmetics, or electronics require different materials.

- Consider Functionality – Will the box need ventilation, tear lines, or both?

- Select Material Strength – Corrugated for heavier items, Kraft for eco-friendly ones.

- Evaluate Design Goals – Brand visibility vs. simplicity.

- Order Prototypes – Always request samples before full production.

Sustainability and Eco-Friendliness

Modern consumers prefer eco-conscious packaging. Perforated boxes made from recyclable Kraft or post-consumer waste cardboard help brands meet sustainability goals. Many suppliers now offer soy-based inks and biodegradable coatings, making packaging safe for the environment.

Popular Uses of Custom Perforated Boxes in the Market

- Subscription Boxes: Tear-away design makes unboxing exciting.

- Gift Packaging: Premium printed perforated boxes add luxury appeal.

- Retail Display Boxes: Easy tear-top design converts the box into a counter display.

- Shipping Boxes: Perforation allows easy access without knives or cutters.

- Food Takeaway: Ventilated perforations keep food hot yet moisture-free.

Frequently Asked Questions (FAQs)

1. What are perforated boxes used for?

Perforated boxes are used for easy-opening packaging, product display, and ventilation. They are common in food, retail, and pharmaceutical industries.

2. Can I customize the perforation pattern?

Yes. You can choose linear, circular, or die-cut perforation patterns depending on your product type and box design.

3. What materials are best for perforated boxes?

The best materials include Kraft paper, cardboard, and corrugated board. Kraft is ideal for eco-friendly brands, while corrugated suits heavy items.

4. Are custom perforated boxes recyclable?

Absolutely. Most perforated Product boxes are made from 100% recyclable and biodegradable materials.

5. How much do custom perforated boxes cost?

Prices start from $0.25 for small boxes and can go up to $1.50 for larger or premium printed designs.

6. Can these boxes be printed with my brand logo?

Yes, you can print your logo, tagline, barcode, or product image using offset or digital printing techniques.

7. Are perforated boxes food-safe?

Yes, when manufactured using FDA-approved food-grade materials, they are perfectly safe for direct or indirect food contact.

8. What’s the difference between perforated and die-cut boxes?

Perforated boxes include dotted tear lines, while die-cut boxes have shaped cutouts. Many boxes combine both for enhanced usability.

9. What is the lead time for custom orders?

Typically, it takes 7–15 business days for design, production, and delivery, depending on the order size.

10. Do perforated boxes help with product display in retail stores?

Yes. They’re widely used as display-ready packaging—the box converts into a retail display unit when the perforated top is removed.

Conclusion

Custom perforated boxes are more than just containers—they are functional design tools that elevate both product usability and brand experience. Their adaptability across multiple industries—from food and pharmaceuticals to retail and cosmetics—makes them one of the most efficient packaging solutions available today.

With customizable sizes, materials, printing, and eco-friendly options, these boxes not only protect and promote your products but also enhance consumer satisfaction through convenience and creativity.

If your business needs a packaging solution that combines aesthetic appeal, easy usability, and sustainability, custom perforated boxes are the perfect fit.